The automotive and aeronautics industries are two of the most important within the Spanish manufacturing sector, accounting for 11% of the country’s GDP between them.

Competitiveness of these two sectors and, in general, of the Spanish manufacturing sector, increasingly depends on their capacity to produce high added value and differentiated products in an efficient and sustainable manner, based on reduced production costs, guaranteeing their quality and minimising time to market. This requires a change in the manufacturing paradigm through the introduction of new smart manufacturing technologies that ensure both production efficiency (through flexible and reconfigurable production systems) and the quality of the manufactured product, guaranteeing an efficient manufacturing model, especially in the case of the increasingly frequent and necessary manufacture of short batches, derived from the massive customisation of products, whose life cycles are becoming ever shorter.

COMIC’s main objective is to research new concepts for integrated and efficient manufacturing of multi-material components based on defining a digital architecture that enables flexible and intelligent manufacturing (through integrated management of data flow in the design, engineering and manufacturing phases) combined with the development of advanced manufacturing technologies (surface treatment, pre-forming, joining, forming and post-processing), based on the features required to manufacture the component.

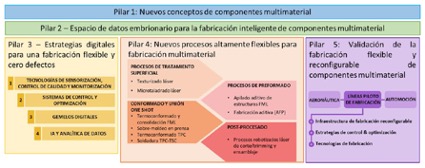

The project is based on 5 pillars (Figure 1):

- Pillar 1 – Developing new concepts for multi-material components.

- Pillar 2 – Developing an embryonic data space for smart manufacturing of multi-material components

- Pillar 3 – Developing digital strategies for flexible, zero-defect manufacturing

COMIC MISSIONS: MIG-20221004 - Pillar 4 – Developing new highly flexible processes for multi-material manufacturing

- Pillar 5 – Testing flexible and reconfigurable manufacturing of multi-material components in 3 use cases (2 from the Automotive sector and 1 from the Aeronautics sector).

Figure 1 COMIC Development Pillars

The COMIC consortium is formed by the following organisations:

DGH ROBOTICA AUTOMATIZACION Y MANTENIMIENTO INDUSTRIAL, SA – DGH is a leading company in the automotive sector within the advanced automation field. It has its headquarters in Valladolid and other work centres in Madrid, Vigo and Barcelona, where it has fully equipped workshops to develop, manufacture and test prototypes and pilot lines for R&D activities.

AUTOTECH ENGINEERING, SL – AUTOTECH, based in Amorebieta-Etxano, is the global R&D centre for the GESTAMP group’s chassis components, and focuses on designing and developing chassis products and assembly and forming technologies. It has specific forming presses and tooling to manufacture hybrid metal-composite components, which it will make available to the project.

SOFITEC AERO, SL – SOFITEC, based in Seville, develops integral aerostructure manufacturing, assembly and repair solutions in composite and metallic materials for the aerospace industry, where it is a recognised and consolidated TIER1. It has production and assembly facilities for both metallic and composite components, which it will make available to the project.

FAGOR ARRASATE SCOOP – Based in Arrasate, FAGOR is an internationally recognised manufacturer of stamping systems and presses, coil slitting machines, and metal component processing lines and machines. It will provide the project with 2 presses for forming automotive products. It has its own R&D&I centre (KONIKER).

INDUSTRIA ESPECIALIZADA EN AERONAUTICA S.A. – INESPASA is a Seville based company with over 30 years of experience in developing integral solutions for aerostructure projects: Design and Manufacture of Tooling, Manufacture of Machined Elements and Assembly of Sub-assemblies.

NUNSYS, SA – Based in Paterna, NUNSYS is a well-established ICT company which is a strategic partner, from a digital transformation point of view, for leading technology manufacturers in multiple sectors. Its Software department will be heavily involved in COMIC, assigning a significant number of analysts and coders with knowledge in the different technologies required for project development.

ENDITY – ENDITY, based in Elgoibar, was born as a spin-off from IDEKO TC and is a recognised player in the development of stand-alone NDT solutions, both integrable and independent, for applications in different industrial sectors. It has specific test benches, inspection heads and customised NDT scanners that it will make available for project developments.

MANAGING COMPOSITES, SL – Based in Madrid, MANAGING COMPOSITES is an engineering company focused on developing the designs and all types of simulations necessary to support the design and obtain a final product in accordance with the requirements set out in different sectors. It has several workstations and general purpose and specific CAD/CAE licences for composite press forming processes, as well as access to and use of a small workshop for the assembly, characterisation and validation of prototypes, which it will make available to the project.

In addition, several prestigious technology centres shall also participate as subcontracted entities, such as: IDEKO, ITI, KONIKER, TEKNIKER and AIMEN.

This project has been subsidised by the Centro para el Desarrollo Tecnológico Industrial (CDTI) and is co-financed by European funds from the Recovery and Resilience Mechanism, as part of the 2021 MISIONES Programme, within the framework of the State Programme to Catalyse Innovation and Business Leadership, of the State Plan for Scientific, Technical and Innovation Research 2021-2023, with the support of the Spanish Ministry of Science and Innovation.