Large-scale part manufacturing requires the implementation of a global data management and end-to-end automation methodology based on worker-centric tools to ensure manufacturability, quality and precision in large part manufacturing from the initial product design.

PENELOPE aims to develop a global digital manufacturing solution that enables a two-way data flow for a seamless integration of the manufacturing process.

Objectives:

- Closed-loop two-way data flow. Developing a two-way data flow throughout the manufacturing chain to enable new models of precision manufacturing based on the characteristics of the large product to be adopted.

- Worker-centred tools. Deploying worker-centred tools that assist in the execution of labour-intensive tasks, while preserving the specific knowledge and skills of the operator.

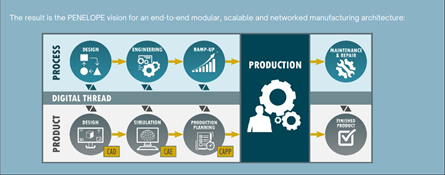

- Digital Architecture. Deploying a digital architecture for modular, reconfigurable, scalable and distributed production for large parts.

- Full-scale demonstrators. Demonstrating PENELOPE’s full-scale approach to more accurate manufacturing of large components (TRL7).

- Zero-defect manufacturing. Developing a zero-defect manufacturing strategy combining process control, quality assurance and Artificial Intelligence.

Ambition:

Large-scale part manufacturing and repair, typically single components, is a complex and challenging process that requires an integrated methodology capable of ensuring manufacturability, quality and high product accuracy in the engineering stages, e.g. design, simulation/modelling and production planning, to be implemented. In this regard, it is important to note that Europe is leading the way in large-scale manufacturing of complex components with world-class manufacturing companies (e.g. AIRBUS, FOKKER, MV WERFTEN, ENI, ALSTOM).

Demonstrators:

PENELOPE shall be implemented on four pilot lines in key manufacturing sectors and supported by a pan-European network of open technology pilots and demonstrators, facilitating the access of its developments to all European manufacturing companies. PENELOPE shall be implemented, validated and demonstrated on real-scale industrial pilot lines in different strategic industrial sectors: oil and gas, shipbuilding, aeronautics and bus and coach body assembly.

Further information: https://penelope-project.eu

This project has received funding from the European Union’s Horizon 2020 Research and Innovation Programme under Grant Agreement No. 958303.

The project consortium includes 31 partners including industrial end-users, technology providers and research institutions.