Rapid Reconfiguration of Flexible Production Systems

The ReCaM project is a three year project funded by the European Commission in the Horizon 2020 programme under Grant agreement No: 680759. The project consortium involves nine partners from industrial end users, technology providers and research institutions.

This project aims to demonstrate a set of integrated tools for the rapid and autonomous reconfiguration of agile production systems, both at operational as well as tactical levels, integrated with the existing production planning and scheduling tools (MES) at a higher technological readiness level (TRL 7). This approach is based on intelligent plug-and-produce capable self-describing mechatronic objects, which are able to auto-program and self-adjust to the required task by utilizing parametric capabilities. These next generation flexible production systems and the proposed set of enabling ICT tools will allow a rapid and cost-efficient reaction to dynamic market changes, also in small-lot production contexts, reducing the efforts needed to switch between product types and production quantities.

ReCaM-solutions are expected to allow increasing the amount of variants and decreasing the lot sizes by 50% in an economically feasible way. Also, at least 30% reduction in set-up and changeover times and costs are expected. The integrated planning tool will take into consideration the energy consumption of the specific resources and try to minimize it by smart production scheduling, utilization of integrated operating-point switching of mechatronic objects, and reconfiguration. Thus, at least 5% reduction in energy consumption is anticipated.

The project will ground on existing de-facto standards and specifications regarding reconfigurable system architectures, resource data models, control architectures and interfaces, and will provide and supplement new specifications for the missing aspects. The ReCaM consortium sees strong involvement of SME’s to RTD and demonstration activities and two end-users from major EU sectors, thus enabling proper exploitation of the demonstrated results worldwide.

Project Objectives:

The ReCaM approach is based on intelligent plug-and-produce capable self-describing mechatronic objects, which are able to auto-program and self-adjust themselves to the required task by utilizing parametric capabilities. The project will make use of existing de-facto standards and specification regarding reconfigurable system architectures, resource data models, control architectures and interfaces when coherent with projects goals, providing and supplementing new specifications for the missing aspects. These new generation flexible production systems and the proposed set of integrated tools will allow a rapid and cost-effective reaction to dynamic market changes, reducing the efforts needed to switch between product types and production quantities. Therefore, ReCaM is expecting to bring the following potential impacts:

- Enabling existing production systems to produce on average at least 50% smaller lot sizes.

- Increase 50% more product variations in an economical way to existing production systems.

- Reduction of at least 30% of the set-up and changeover times and costs for existing production systems leading to a significant increase in production capacity.

- Reduction of average energy consumption by 5% through an optimised use of production capacity.

- Strong support for standardisation of communication protocols, data structures and tool connectivity

The developed innovative and integrated tools within ReCaM will increase the competitiveness and attractiveness of European companies:

- By increasing customer satisfaction, offering an economical production of a wider range of customized products.

- By increasing the service level with a demand driven production, both in terms of production volume and variety of customer requests.

- By improving the production capacity, with an optimal usage and configuration of production resources, and with an overall reduction of lead times and time-to-market.

- By reducing the overall energy consumption, with a more rational configuration of production resources enabling cost savings on the overall production and a reduction of carbon footprint for production plants.

- By increasing the capability of tackling diversified markets/customer requirements in a cost-effective manner.

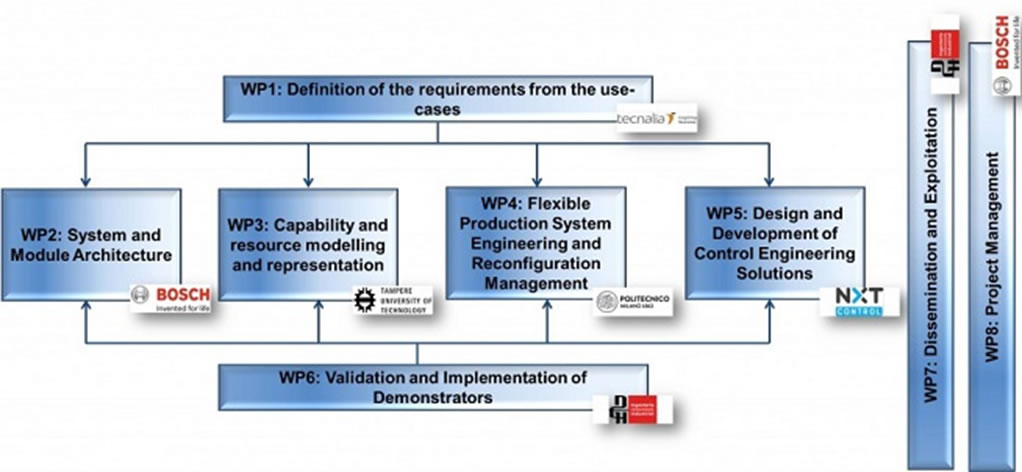

Project structure

- The project approach and strategy according to the organization of Work packages (WPs) is illustrated here.

Consortium Partners